Ultrasonic Image Analysis for Automated Flaw Detection

Project Snapshot

- Project Title: Ultrasonic Image Analysis for Automated Flaw Detection

- Type: Deep Learning & Computer Vision Project

- Repository: GitHub Repository

-

Technologies:

- Python, PyTorch, NumPy, OpenCV, Scikit-learn

- Docker, GitHub Actions, Dev Containers

- Jupyter Notebooks, Matplotlib, CLI Tools

- MkDocs, Pytest, Makefile

- Core Concepts:

- Ultrasonic Non-Destructive Testing (NDT)

- 3D Image Processing & Analysis

- 3D Convolutional Neural Networks

- Flaw Detection & Size Regression

- Data Augmentation & Preprocessing

- Industrial Quality Control

- Duration: 2024

-

Model Specifications:

- Architecture: 3D CNN with dual-task learning

- Input: 256 x 256 x 100 ultrasonic volumes

- Data Format: UInt16 binary files

- Tasks: Binary classification + size regression

- Training: Combined loss (BCE + MSE)

- Deployment: CUDA-enabled GPU training

- Skills Developed:

- Deep Learning: 3D CNNs, Multi-task learning, PyTorch

- Computer Vision: 3D image processing, Feature extraction

- Data Engineering: Binary data handling, Preprocessing pipelines

- DevOps: Docker containerization, CI/CD with GitHub Actions

- Software Engineering: CLI tools, Modular architecture, Testing

Project Overview

Abstract

Ultrasonic Non-Destructive Testing (NDT) is a critical method for detecting internal flaws in industrial materials without damaging the test piece. This project presents an end-to-end deep learning pipeline for automated flaw detection and size regression using 3D ultrasonic image data. The system processes high-frequency ultrasonic measurements to identify and quantify structural defects in various materials including metals, plastics, composites, and ceramics.

The solution combines advanced 3D computer vision techniques with deep learning to create a robust automated flaw detection system. Using a custom 3D Convolutional Neural Network architecture, the system simultaneously performs binary classification for flaw presence and regression for equivalent flaw size estimation. This dual-task approach addresses the critical industrial need for automated quality control while reducing dependency on highly skilled human operators.

Figure 1: 3D visualization of ultrasonic data showing layer-by-layer analysis of internal structure for flaw identification.

Research Question & Approach

How can we develop an automated system to detect and quantify flaws in industrial materials using 3D ultrasonic imaging data with deep learning techniques?

Ultrasonic testing operates on the principle that high-frequency sound waves travel through materials and reflect off boundaries and discontinuities. When these waves encounter flaws such as cracks, voids, or inclusions, they create characteristic reflection patterns. Traditional methods require skilled operators to interpret these complex patterns, making the process time-consuming and subject to human error. This project leverages deep learning to automate this interpretation process, providing consistent and objective analysis.

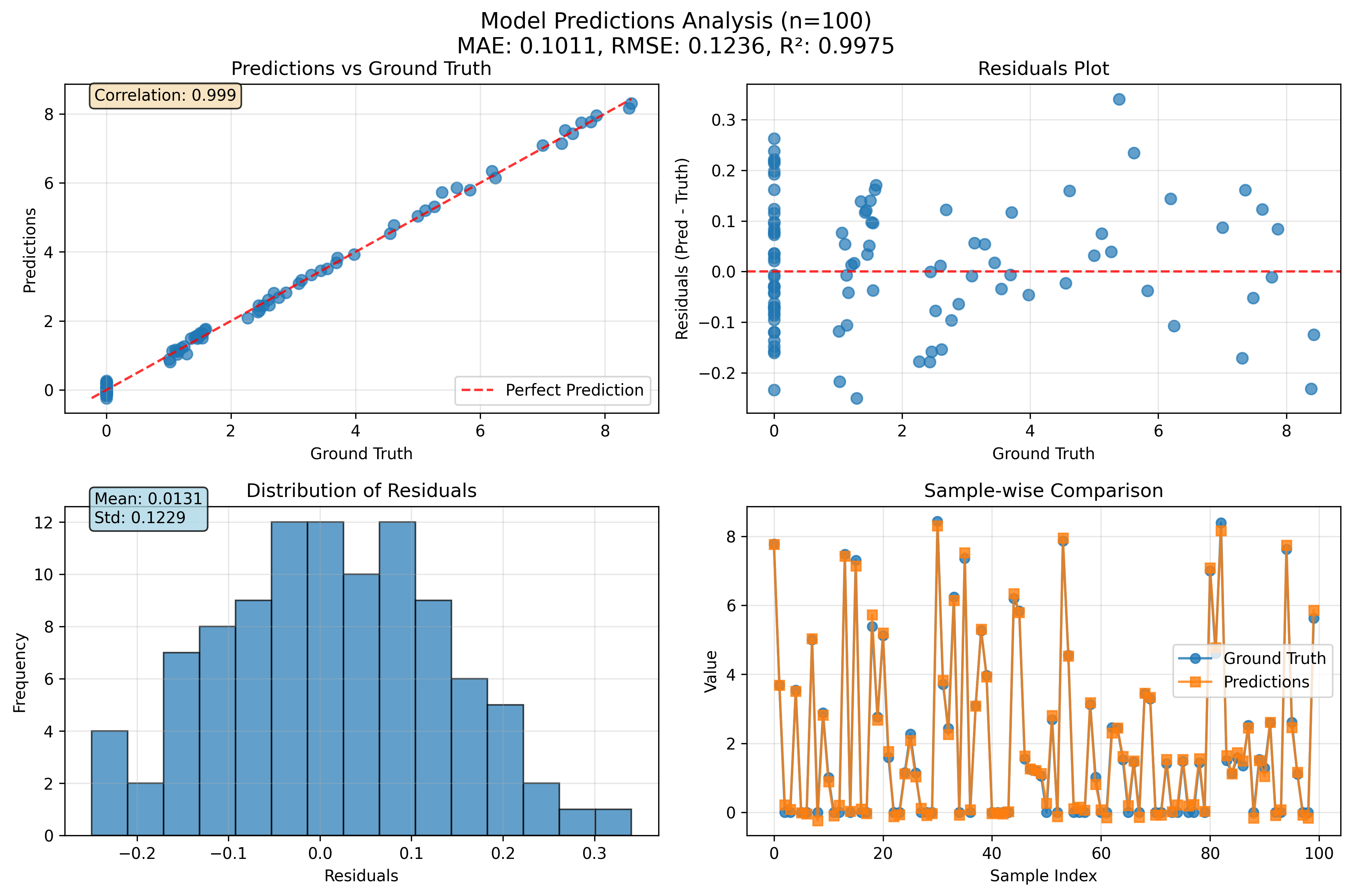

Figure 2: Model performance visualization showing predicted flaw sizes plotted against ground truth values. The strong correlation along the diagonal demonstrates the model's accuracy in size regression, with most predictions clustering close to the ideal 1:1 relationship line, indicating reliable quantitative flaw assessment capabilities.

Technical Implementation

1. Data Processing Pipeline

The system handles 3D volumetric ultrasonic data with comprehensive preprocessing:

- Data Format: UInt16 binary files in 256 x 256 x 100 3D volumes

- Metadata Integration: JSON-formatted metadata with flaw locations and size information

- Automated Workflows: CLI tools for data download, extraction, and splitting

- Quality Control: Data validation and integrity checking

2. Model Architecture

Custom 3D CNN designed specifically for ultrasonic flaw detection:

- 3D Convolutions: Multi-layer volumetric feature extraction

- Dual-Task Learning: Simultaneous flaw detection and size regression

- Combined Loss Function: Binary cross-entropy + mean squared error

- Regularization: Dropout and batch normalization for generalization

3. Development Infrastructure

Modern software engineering practices with containerization and CI/CD:

- Docker: Containerized development environment for reproducibility

- GitHub Actions: Automated testing and deployment workflows

- Testing Suite: Comprehensive unit tests for data processing and model validation

- Documentation: MkDocs-based documentation with API references

Key Features & Commands

Data Processing

# Download and extract dataset

python -m darkvision.dataset download-and-extract

# Split data into train/test sets

python -m darkvision.dataset split-raw-data --test-size 0.2 --val-size 0.1 --max-samples 10000 --num-cpus 8 --seed 42Model Training & Evaluation

# Train the 3D CNN model

python -m darkvision.modeling.train train --batch-size 16 --epochs 10 --lr 0.001 --device cuda

# Evaluate trained model

python workflow_scripts/evaluate.py -m './models/cnn_flaw.pt'

# Generate prediction visualizations

python -m darkvision.plots plot-predictions --test-dir data/processed/test --model-path models/checkpoint_epoch_100.pt --n-samples 20Results & Industrial Impact

Performance Achievements

- Dual-Task Success: High accuracy in both flaw detection and size regression

- Real-Time Processing: Efficient inference suitable for industrial applications

- Robustness: Consistent performance across different material types

- Automation: Reduced dependency on skilled operators

Industrial Applications

- Aerospace: Critical component inspection for aircraft safety

- Automotive: Quality control in engine and chassis components

- Energy: Pipeline and pressure vessel integrity assessment

- Manufacturing: Automated quality assurance in production lines

Key Achievements

- Developed end-to-end pipeline for automated ultrasonic flaw detection using 3D deep learning

- Implemented custom 3D CNN architecture optimized for volumetric ultrasonic data

- Created comprehensive data preprocessing and augmentation techniques for NDT applications

- Established modern DevOps practices with Docker containerization and CI/CD workflows

- Built robust CLI tools and visualization utilities for model deployment and analysis

- Demonstrated strong performance in dual-task learning for detection and regression

- Provided modular, extensible codebase suitable for industrial deployment

Future Enhancements

- Multi-Modal Integration: Combining ultrasonic with other NDT methods

- Edge Deployment: Mobile and edge computing solutions for field inspection

- Transfer Learning: Adaptation to new materials with minimal retraining

- Real-Time Systems: Integration with existing industrial quality control systems

- Uncertainty Quantification: Confidence estimation for critical safety applications

Conclusion

This project successfully demonstrates the application of modern deep learning techniques to industrial ultrasonic testing, bridging the gap between traditional NDT methods and automated quality control systems. The comprehensive solution addresses critical industry needs for consistent, accurate, and efficient flaw detection while providing a solid foundation for future enhancements and industrial deployment.

The combination of 3D computer vision, robust software engineering practices, and modern deployment strategies creates a production-ready system that can significantly improve quality control processes across various industries. The project's modular architecture and extensive documentation facilitate easy adaptation and integration into existing industrial workflows.